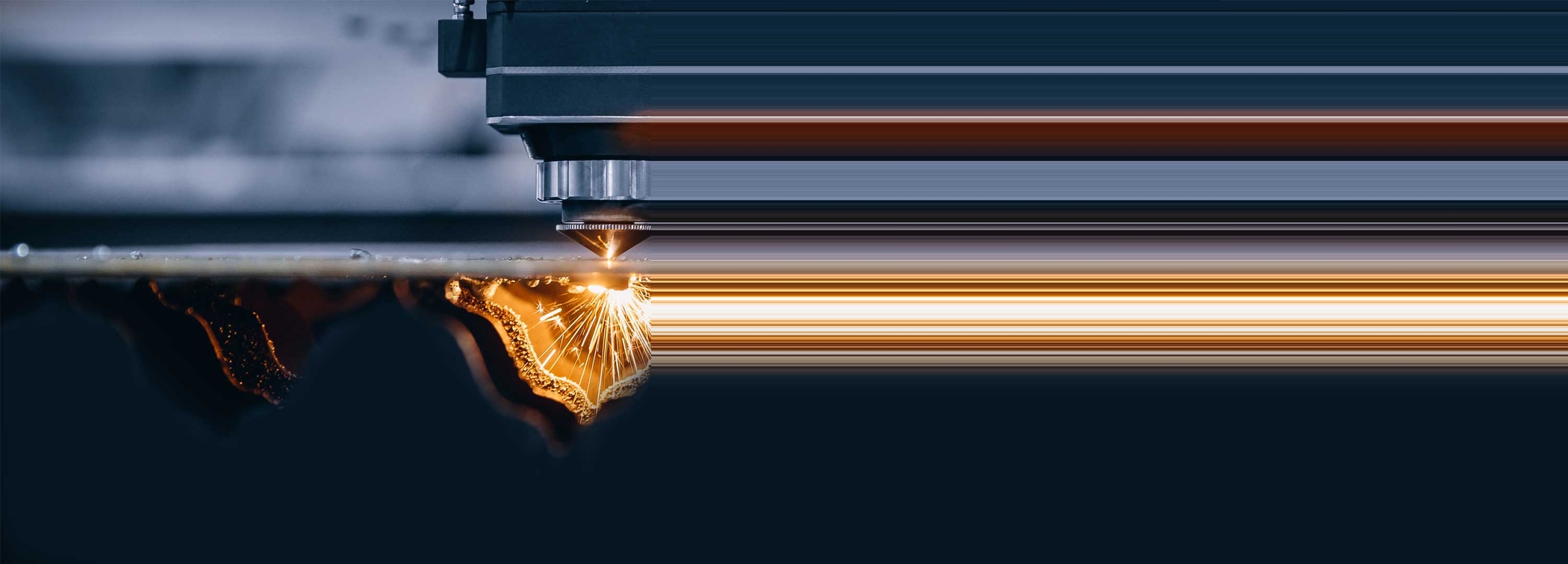

The pressure is on to keep pace with Industry 4.0. Manufacturers must adapt to emerging technologies like AI, while maintaining efficiency and managing a growing web of devices, apps and tools.

Your factories already operate at “the edge.” But unifying your systems in a secure, integrated edge computing platform opens up powerful opportunities to overcome challenges and strengthen operations for tomorrow.

In this blog, we’ll explore the key challenges facing modern manufacturing and how edge computing can help overcome them.

The impact of outdated legacy technologies

Contents

- 1 The impact of outdated legacy technologies

- 2 Break down data silos for holistic operations

- 3 Strengthening security in the manufacturing sector

- 4 Business continuity in remote locations

- 5 Address the expertise crisis with smarter automation

- 6 How SUSE Edge solutions can transform your manufacturing operations

Manufacturing companies often rely on legacy systems that have been in place for decades. Outdated systems can hinder innovation, making it difficult to integrate new technologies. For example, if legacy systems do not support the latest IoT devices or advanced analytics, you lose out on powerful real-time decision-making — and risk getting left behind.

But as high-demand products roll off the line at peak production, it’s too costly to shut down or pause production lines to transition to a more modern, hybrid infrastructure. Despite demand and necessity, manufacturers simply can’t afford to stop running legacy systems.

In turn, this leads to an IT and OT landscape filled with disparate systems. However, the right edge solution enables seamless data integration, unifying digital and physical operations to deliver new insights and enhance efficiencies.

By integrating edge computing with existing legacy systems, manufacturers can extend the life of their current infrastructure while gaining the benefits of modern technology.

Break down data silos for holistic operations

Data silos are a common issue in manufacturing. Different departments and systems operate independently, leading to fragmented data and insights — resulting in inefficiencies, missed opportunities and poor decision-making. For instance, production data might be stored in one system, while supply chain data is in another, making it difficult to optimize the entire operation.

Edge computing brings computing power and data processing closer to production lines, teams, and equipment. More data connectivity enhances performance and empowers technologies like AI-driven predictive maintenance, even in areas with limited connectivity. Edge solutions help manufacturers streamline workflows, maximizing resource or supply allocations, especially where talent may be scarce or limited.

Strengthening security in the manufacturing sector

Cybersecurity is a growing concern for manufacturing companies. With the increasing number of connected devices and the rise of industrial IoT, the attack surface has expanded significantly. A single breach can have severe consequences, including production downtime, data loss and reputational damage.

Edge computing in manufacturing can play a crucial role in enhancing cybersecurity. Edge solutions improve security by applying unified security practices to every machine and device, wherever it’s located. By processing data locally, edge devices can reduce the amount of data that needs to be transmitted over the network, minimizing the risk of data breaches. Each site or device can also maintain its own operational data controls, easing data governance and allowing device- or location-specific governance applications.

Business continuity in remote locations

Manufacturing operations often span multiple locations, including remote sites with limited connectivity. Maintaining operations in these areas can be challenging, as network outages can disrupt data flow and production processes. Edge computing can help ensure business continuity by enabling local data processing and decision-making.

With edge computing, critical operations can continue even when the network is down. For example, a remote factory can use edge devices to monitor and control machinery in real-time, without relying on a central data center. This can help prevent production delays and ensure that operations run smoothly, even in low-connectivity environments.

Address the expertise crisis with smarter automation

Along with these challenges, the manufacturing industry is also facing an expertise crisis. Skilled workers are retiring, and there is a growing shortage of talent to replace them. To address this issue, manufacturers are turning to automation and advanced technologies.

Edge computing supports smarter industrial automation by providing the necessary compute power and data processing capabilities at the edge. For example, edge devices can be used to deploy AI and machine learning algorithms that optimize production processes, predict maintenance needs and improve quality control.

Edge solutions help manufacturers streamline workflows and maximize resource or supply allocations, especially where talent may be scarce or limited.

How SUSE Edge solutions can transform your manufacturing operations

At SUSE, we understand the unique challenges facing the manufacturing industry. Our edge computing solutions are designed to help manufacturers overcome these challenges and stay ahead of the competition.

Our purpose-built for rugged, far-edge environments and industrial IoT, to ensure manufacturers aren’t forced to compromise with legacy tech or limited hardware choices.

Here are some key benefits of SUSE Edge:

- Security at the edge: Our edge solutions are built with robust security features to protect your data and operations. Real-time monitoring and threat detection help you stay one step ahead of potential security incidents.

- Business continuity: SUSE Edge ensures that your operations continue to run smoothly, even in remote or low-connectivity environments. Local data processing and decision-making help prevent production delays.

- Advanced technologies: Our solutions support the deployment of AI, machine learning and digital twins, enabling you to leverage the latest technologies for improved performance and innovation.

- Cost-effective: By integrating with your existing infrastructure, SUSE Edge helps you modernize your operations without the need for a complete system overhaul. This can save you time and money while providing the benefits of modern technology.

To stay competitive and innovative, companies must address the challenges of outdated legacy systems, data silos, cybersecurity threats, limited connectivity and the expertise crisis. Edge computing is crucial to meeting these challenges, enabling manufacturers to modernize their operations, improve security and support advanced technologies.

At SUSE, we are committed to helping manufacturing companies stay ahead of the curve.

(Visited 1 times, 1 visits today)