As the manufacturing industry modernizes, advanced technologies allow edge devices to process and act upon data right where it’s collected — on the factory floor, in remote facilities or anywhere operations happen.

Connecting IT and OT with edge computing improves data insights, but it also introduces new threats to cybersecurity and operational resiliency.

Protecting sensitive data, reducing the attack surface and maintaining compliance are all critical aspects of securing a manufacturing environment from an IT perspective. This blog explores how modern manufacturing companies can enhance their cybersecurity with the help of open source edge solutions.

Protecting sensitive data in manufacturing environments

Contents

Manufacturing environments handle a vast amount of sensitive data, including production data, intellectual property and customer information. The reputation of the company hinges on the protection of this data; a data breach can lead to significant financial losses, legal liabilities and damage to customer trust.

To secure sensitive data, manufacturing companies must implement robust data protection measures. This includes:

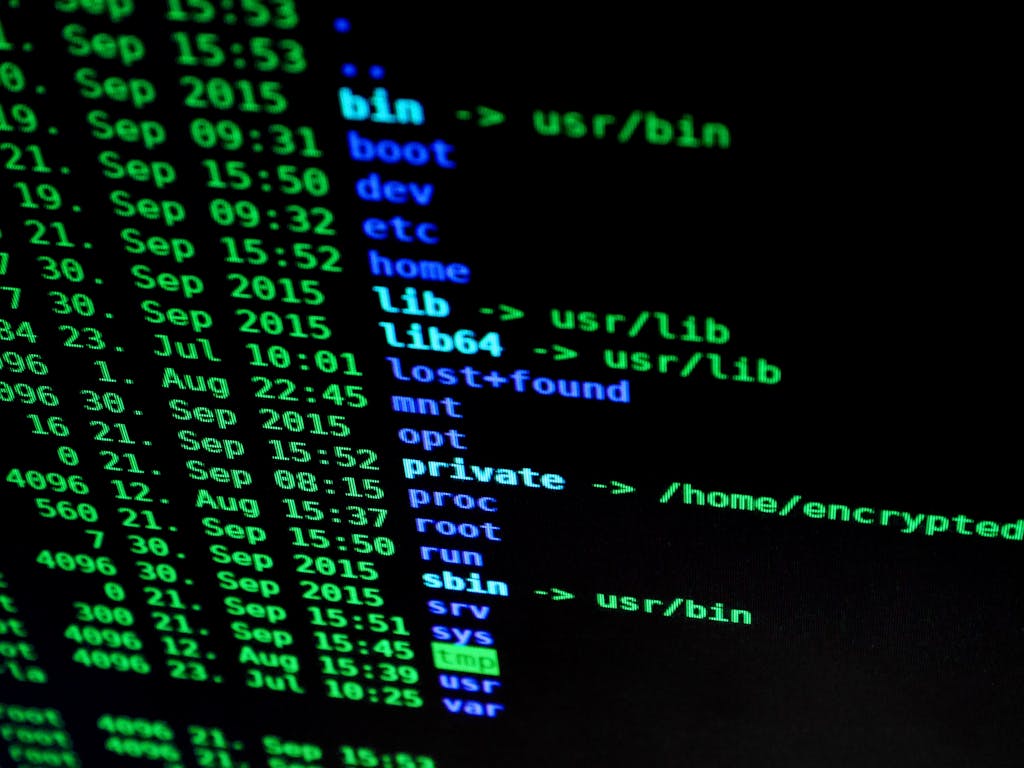

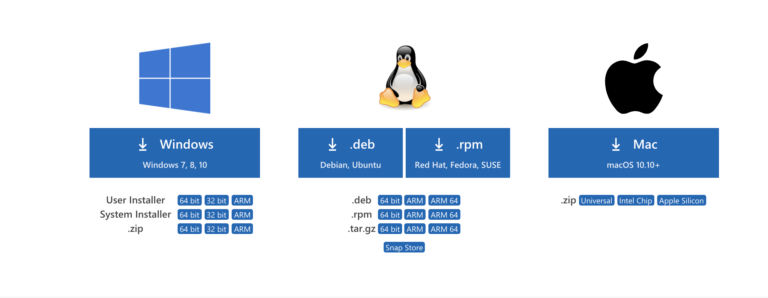

- Encryption: Encrypting data both in transit and at rest to prevent unauthorized access.

- Access controls: Implementing strict access controls to ensure that only authorized personnel can access sensitive data.

- Regular audits: Conducting regular security audits to identify and address vulnerabilities.

Unified security practices for reduced attack surface

One of the biggest challenges in manufacturing cybersecurity is the large attack surface created by the integration of IT and OT systems. Traditional IT security practices often do not extend to OT systems, leaving gaps that can be exploited by cybercriminals.

Edge computing can significantly reduce the attack surface by processing data locally and reducing the amount of data transmitted over the network. This localized processing minimizes the risk of data breaches and makes it easier to implement unified security practices across both IT and OT systems. By deploying edge devices that are designed with security in mind, manufacturers can create a more resilient and secure network.

Compliance and data governance in manufacturing

Compliance with industry regulations is a critical aspect of manufacturing cybersecurity. Regulations such as GDPR and ISO standards require manufacturers to implement strict data governance practices to protect sensitive information.

Edge computing can help ensure compliance by providing secure and controlled data processing and storage. Each site or device can also maintain its own operational data controls, easing data governance and allowing device- or location-specific governance applications.

Centralized edge solutions can also provide detailed logs and audit trails, making it easier to demonstrate compliance during audits.

Security features for evolving threats

The threat landscape is constantly evolving, with new vulnerabilities and attack vectors emerging regularly. Manufacturing companies need edge solutions that offer robust security features to protect against these evolving threats.

Key security features to look for in edge solutions include:

- Encryption: Strong encryption algorithms to protect data in transit and at rest.

- Secure boot: Secure boot processes to prevent unauthorized access and ensure the integrity of the system.

- Real-time threat detection: Advanced threat detection capabilities to identify and respond to security incidents in real-time.

- Regular updates: Frequent security updates to patch vulnerabilities and protect against new threats.

How SUSE Edge solutions for manufacturing cybersecurity

At SUSE, we understand the unique security challenges facing the manufacturing industry. Our edge computing solutions are designed to help manufacturers protect their operations and stay ahead of the competition.

Here’s how SUSE Edge enhances your edge security:

- Protect sensitive data: SUSE Edge solutions use advanced encryption and access controls to secure sensitive data, ensuring that your intellectual property and customer information are protected.

- Reduce attack surface: By processing data locally and implementing unified security practices, SUSE Edge helps minimize potential points of failure and reduce the attack surface.

- Ensure compliance: Our solutions provide robust data governance features to help you adhere to industry regulations and maintain compliance.

Ensuring cybersecurity in modern manufacturing environments is a complex but essential task. With secure edge solutions, manufacturing companies can create a secure and efficient operational environment

To learn more about how SUSE Edge can help you ensure cybersecurity in your manufacturing operations, download our white paper, “Future-Ready Manufacturing: Gain the Edge Advantage.”

(Visited 1 times, 1 visits today)